Discourse about 3D printing tends to revolve around sustainability, which is, of course, a major benefit of using the technology if using recycled plastic or biomaterials. But 3D printing can be used to reach certain objectives like high customization compared to traditional techniques and crafting a cohesive brand identity. See five stores that are using the technology innovatively.

3D printing puts sustainable values into practice

Ecoalf’s retail space at the Las Rosas Village shopping centre in Madrid embodies the brand’s commitment to sustainability with a 3D-printed interior made of 100 per cent recycled plastic. Design studio Nagami, which specializes in the 3D printing of large-scale products, repurposed 3,300 kg of recycled plastic to create an installation for the 90-sq-m store. Resembling melting glaciers, the walls, tables and display shelves are a reminder of the effect rising global temperatures have on polar ice caps. The pieces were manufactured in Spain to reduce their environmental footprint and can be fully recycled at the end of their lifespan. The Ecoalf store demonstrates how new technologies can turn waste into building blocks for commercial spaces. Retailers, in turn, can have customizable spaces while leaving a lighter footprint.

Sustainable spatial design develops a more integrated brand identity

Coffee retailer Dolce Gusto puts its Neo product on display at its flagship store, designed by Estudio Guto Requena, in a park in São Paulo. The store’s shelled form was conceived using a parametric design process and made with a 3D printer, making the structure one of the first of its kind on the continent. Its shape mimics that of a coffee plant flower, with the biodegradable plaster roof appearing light and delicate as if fabric draped over a timber skeleton. As the visitor walks along the urban park’s meandering paths, they come across the store’s open structure and are welcomed through one of five ‘petals’. Shelves and product displays are built into the fundamental timber body of the store, generating a unified look and freeing up the central space for coffee tasting and socialization. Leveraging innovative computing technologies and 3D printing, the coffee retailer uses its São Paulo flagship store to give its future-facing, sustainable visions spatial form, helping develop a more integrated brand identity.

Parametric design accomplishes highly customizable interiors

Jewellery brand La Manso opened a store in Barcelona populated by 3D-printed elements echoing the city’s architecture. The project – a collaboration between La Manso and design studio External Reference – weaves references between the label’s contemporary costume jewellery and Barcelona’s iconic modernist buildings. Located in the city’s Eixample district, the 25-sq-m space is situated at a corner site endowed with a classic stone overhang etched with organic forms. Parametric design techniques and 3D-printing methods enabled the designers to conceive a striking all-white interior, in which custom furnishings seem to engulf the walls. Inside, the façade’s ornaments were reinterpreted as abstract rosettes with futuristic ‘glitches’, and bas-relief elements of varying sizes. Parametric design and 3D printing enable the customization of the shop’s interiors, which could prove to be less accessible via more traditional materials and application techniques.

3D-printed interiors make spaces more experiential

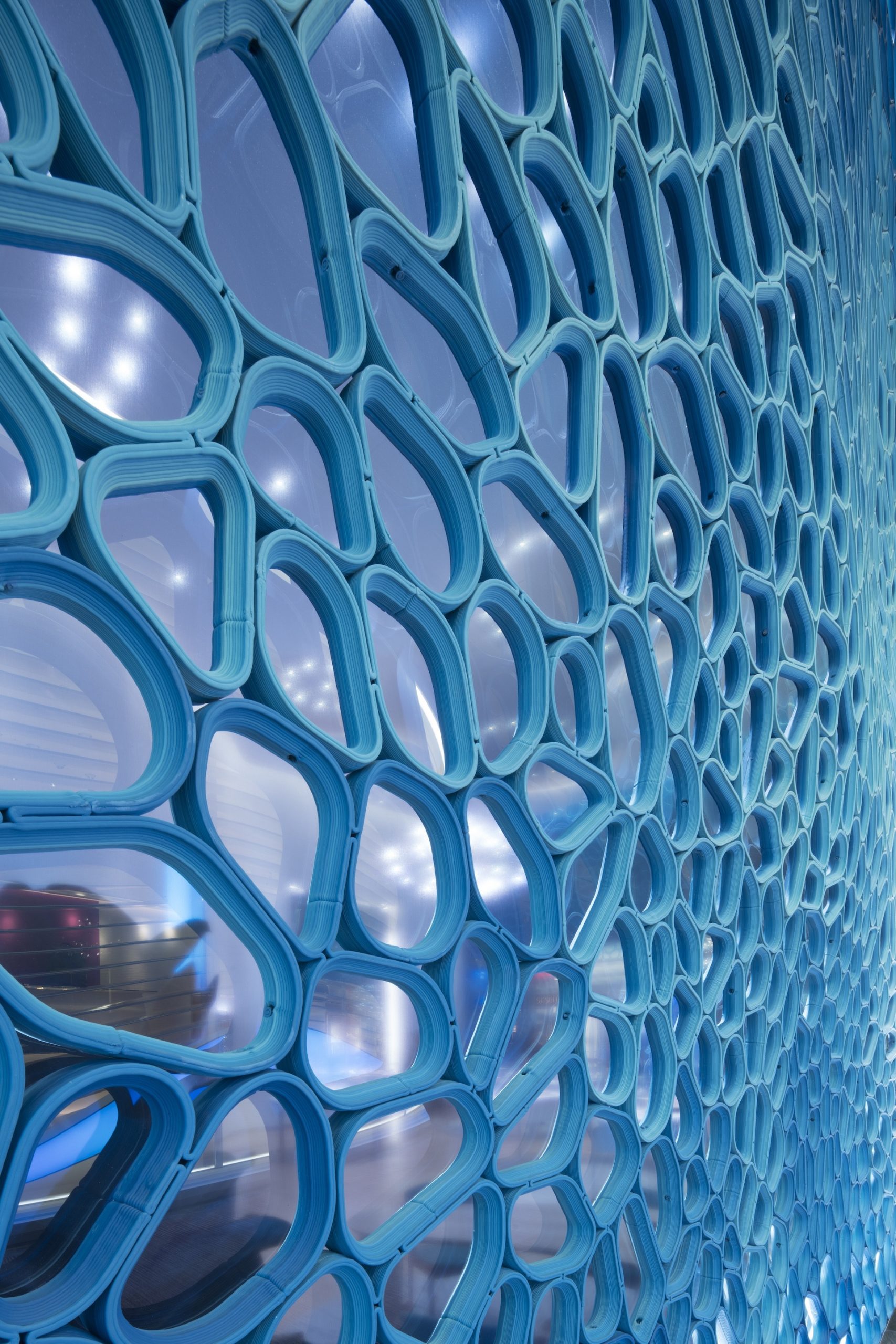

MVRDV designed a 3D-printed façade for luxury jeweller Tiffany & Co’s Terminal 1 Changi Airport store in Singapore. Seeking to balance the essence of Tiffany’s original glass art with the locality, the designer looked to Singapore’s coral reefs. A coral-inspired pattern was designed and printed by Aectual with recycled plastic, including reclaimed and recycled fishing nets. The cell-like formation foregrounds a layer of glass that was screen printed in a colour gradient, transitioning from Tiffany’s robin’s egg blue to a deeper hue further referencing the ocean setting. Tiffany’s innovative approach to its Singapore airport retail space gives customers a reason to visit the store – why should they visit the location if it provides the same experience as elsewhere? The store’s design is unique from other Tiffany outposts and provides a location-specific to entice visitors to shop in the space.

Biomaterials and 3D printing achieve futureproof retail

Design studio WeWantMore was briefed by an eco-friendly Belgian-based optician to create an eyewear store in Begijnendijk, Belgium, with sustainable elements. The timber, mycelium and glass materials that form the Op ‘t Oog shop are durable, sustainably sourced and multipurpose. The real stars of the store are 3D-printed mycelium columns by Blast Studio, formed from recycled coffee cups collected in London. A solid paper foundation enables the mycelium skin to grow. The organic pillars – which are placed in front of large floor-to-ceiling windows – double as product displays and full-length mirrors. Cellulose acetate display plates attached to the pillars and wooden shelves refer to the eyewear’s composition. The materials and methods used to create the store fit-out are a reflection of the brand putting its commitment to sustainable eyewear into practice.